At Don Whitley Scientific (DWS), precision isn’t just a buzzword—it’s a fundamental part of our daily operations, thanks in no small part to our CNC Machine Shop. With substantial investments in cutting-edge machinery and technology, DWS has built a world-class facility that provides essential components for our own manufacturing and offers contract services for other businesses. The CNC shop's capabilities are vast, including 3D CAD modelling, CNC turning, CNC milling, and 3D printing.

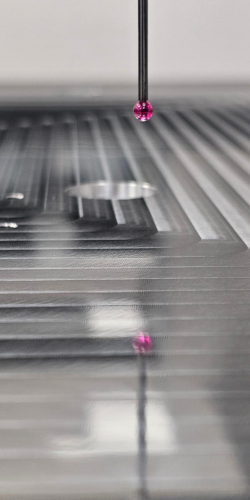

Investments That Drive QualityOne of the latest advancements in our CNC shop is the installation of a Coordinate Measuring Machine (CMM) from LK Metrology. This state-of-the-art equipment allows us to precisely measure physical objects down to 1.3 microns, offering unparalleled accuracy. This precision is crucial for the manufacture of Whitley Workstations, ensuring that every part—from nuts to bolts—is perfectly integrated, enhancing both durability and performance. The investment also streamlines production by moving from paper schematics to digital files, eliminating human error and improving overall quality control. As Fergus Murray, Product Engineering Director at DWS, puts it, “When we say our products are quality, we really mean that—and do everything to ensure we can stand by that claim.” Over the past decade, DWS has committed to self-sufficiency, manufacturing many of the small, intricate parts that make our products stand out in the industry. Collaboration in InnovationThe CNC shop’s work isn’t just confined to Whitley products. We’ve also taken our expertise outside the company with projects for customers such as the PRECISE group in Manchester. We recently began

|

|

upgrading the Proton Beam Therapy (PBT) Hypoxystation, originally installed in 2021 at the Proton Beam Therapy Centre at The Christie NHS Foundation Trust, Manchester. With the CNC shop's contribution, we enhanced the unit’s precision, increased its sample throughput, and enabled real-time monitoring of cellular reactions.

A key part of this upgrade was the creation of a custom-built plate "hotel" system for cell sample storage. The machine shop team worked closely with our research and development team and production engineers to develop a solution that not only addressed design flaws in the original "hotel" that was sourced elsewhere, but also allowed for the addition of new features, such as a second storage unit or a dedicated microscope. The result? A system that offers greater flexibility, reliabilatiy and precision, ultimately improving experimental outcomes.

A Trusted Partner for Quality and Innovation

Whether it's producing high-quality components for Whitley Workstations or collaborating on cutting-edge research projects like the PBT Hypoxystation, the CNC Machine Shop at DWS is an indispensable part of our operation. We combine design expertise, state-of-the-art technology, and a commitment to quality to deliver products and solutions that stand the test of time.

If you’re looking for a partner that can bring both precision and innovation to your project, the DWS CNC Machine Shop is ready to assist.

AT

AT

English

English